Logistics management software is now essential for businesses that store, move, track, and deliver goods. Because supply chains have expanded, real-time accuracy matters more than ever. Companies want faster shipping, lower costs, smoother workflows, and full visibility. With the right logistics system, these goals become achievable, measurable, and profitable. This article explains how logistics management software works, its advantages, core modules, industry applications, selection criteria, implementation tips, and emerging trends.

What Is Logistics Management Software

Logistics management software is a digital platform that automates planning, execution, and monitoring of transportation, warehousing, inventory, and delivery operations. It improves shipment accuracy while reducing manual effort. Every step, from receiving goods to final delivery, becomes visible and trackable. With data-driven decision-making, businesses move products faster and operate with fewer errors.

Why Logistics Management Software Matters Today

Businesses operate in a competitive world where delayed shipments cause revenue loss, customer dissatisfaction, and operational stress. Logistics management software solves these issues through automation, process streamlining, and predictive insights. With fast reporting, team collaboration improves, decision-making becomes stronger, and productivity increases continuously.

Key Features of Logistics Management Software

1. Inventory & Warehouse Management System

With inventory tracking tools, companies receive real-time stock levels, SKU movement history, and demand forecasting. Warehouses stay organized because automation reduces overstocking and stock-outs. Barcode and RFID integration boosts accuracy while improving order fulfillment speed.

2. Transportation Management Tools

Transportation management modules plan routes, track vehicles, and optimize fuel usage. Delivery schedules become efficient as the software suggests the fastest and most cost-effective routes. Fleet monitoring ensures safety, improves driver productivity, and controls unnecessary delays.

3. Order & Shipping Automation

Automation reduces processing time while eliminating manual entry errors. Orders sync automatically across inventory, billing, and shipment systems. Shipping labels, invoices, and tracking numbers generate instantly, so fulfillment teams work faster with confidence.

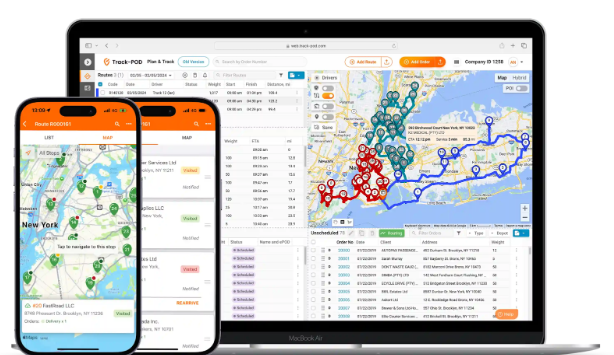

4. Real-Time Tracking & Visibility

Real-time GPS tracking allows managers to monitor freight movement, driver location, and delivery status. With activity timelines and notifications, customers receive accurate ETAs. Route disruptions become manageable through quick rerouting decisions.

5. Reporting, Analytics & Forecasting

Logistics data transforms into useful insights through KPI dashboards and performance reports. Predictive analytics helps businesses reduce expenses, plan workload, and allocate resources intelligently. Highlights in lead time, order accuracy, and fuel consumption become clear.

Benefits of Using Logistics Management Software

1. Cost Reduction

Through optimized routing, fuel control, and better resource planning, logistics management software reduces total operational costs. Automated workflows cut labor hours while eliminating duplication. Over time, improved efficiency delivers long-term financial growth.

2. Faster Delivery & Higher Efficiency

Speed matters in logistics. Automated distribution accelerates picking, packing, and shipping. Warehouse teams handle more orders in less time, so delivery reliability increases. Customers notice consistency, trust builds, and business growth strengthens.

3. Improved Accuracy & Visibility

Human errors decrease because the system maintains accurate records. Shipment tracking offers complete transparency across the supply chain. Managers gain immediate clarity and respond quickly to issues before they become expensive problems.

4. Better Customer Satisfaction

Customers expect fast updates and smooth delivery experiences. With real-time tracking, digital documentation, and quick support handling, businesses meet expectations. Happy customers return, recommend services, and strengthen brand reputation.

5. Scalability & Future Readiness

As businesses expand, logistics software grows with them. Additional warehouses, new shipment routes, increased order volumes integrate smoothly. Future-focused technology keeps companies competitive across evolving markets.

Industries That Use Logistics Management Software

1. E-Commerce & Retail

Online stores depend on automated warehousing, fast order handling, and smooth delivery tracking. Logistics tools reduce cart abandonment by providing reliable delivery times and real-time order updates.

2. Manufacturing

Production units need accurate raw material supply scheduling. Logistics software connects suppliers, manufacturing plants, and distributors for synchronized workflow. Inventory shortages reduce, production delays drop, and final goods reach markets faster.

3. Pharmaceuticals & Healthcare

Medicine delivery must remain fast, secure, and traceable. Logistics systems monitor temperature-controlled shipments, maintain compliance, and protect safety. Hospitals receive supplies without disruption.

4. Food & Beverage

Perishable products demand precise scheduling. With route optimization and cold-chain monitoring, food arrives fresh. Waste reduces, quality improves, and distribution remains consistent.

5. Freight Forwarding & 3PL Companies

Third-party logistics firms streamline multi-client operations using centralized dashboards and automated fleet coordination. Shipment visibility builds trust and increases contract retention.

How to Choose the Best Logistics Management Software

1. Identify Business Needs

Start with analyzing logistics volume, warehouse size, delivery frequency, and reporting requirements. When needs are clear, software selection becomes easier and accurate.

2. Check Integration Compatibility

Software must connect with ERP, CRM, accounting, and e-commerce platforms. Smooth integration eliminates data silos, improves synchronization, and reduces manual syncing errors.

3. Look for Real-Time Tracking & Scalability

Choose systems that support real-time GPS tracking and multi-warehouse expansion. With scalable architecture, future growth remains supported with stability and speed.

4. Evaluate User Interface & Mobile Accessibility

Simple dashboards and mobile apps support field teams, drivers, and managers remotely. Training becomes quick because navigation remains intuitive and user-friendly.

5. Compare Pricing Models & ROI

Investment should align with long-term operational savings. Compare subscription tiers, implementation fees, customization flexibility, and support availability.

Implementation Best Practices

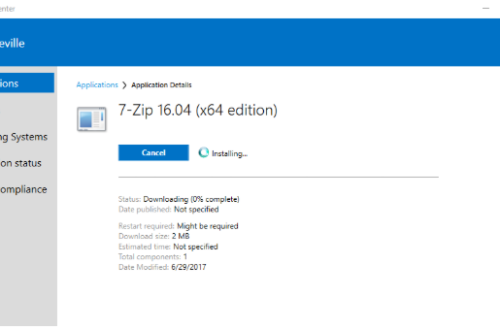

1. Train Teams Effectively

Training drives adoption. Employees must understand dashboards, workflows, and automation tools. Short training cycles help teams adapt quickly with confidence.

2. Use Gradual Deployment

Instead of switching everything instantly, deploy software in phases. Monitor performance, refine processes, and add modules step by step.

3. Monitor KPIs & Optimize Continuously

Track delivery time, picking accuracy, fleet performance, and operational costs. Continuous improvement helps companies scale efficiently.

Future Trends in Logistics Management Software

Artificial intelligence will automate decision-making as predictive analytics improves forecasting accuracy. IoT sensors will enhance shipment monitoring. Drone and autonomous vehicle delivery systems will reshape transportation models. Cloud-based platforms will support global scalability with faster syncing and improved data protection.

Conclusion

Logistics management software transforms supply chain operations through automation, visibility, and accuracy. Because it reduces cost and improves customer experience, every growing business should adopt it to stay competitive. Now is the ideal time to streamline your logistics system, enhance productivity, and scale smarter.

FAQs

1. What is logistics management software used for?

It manages inventory, warehousing, transportation, shipping automation, and real-time tracking.

2. How does logistics software reduce costs?

By optimizing delivery routes, reducing manual tasks, and improving fuel efficiency.

3. Which industries benefit most from logistics software?

E-commerce, retail, manufacturing, healthcare, freight forwarding, and food supply chains.

4. Can logistics software support order tracking for customers?

Yes, it sends real-time tracking updates and delivery notifications.

5. Is logistics management software scalable for growing companies?

Yes, it expands easily with increasing shipments, warehouses, and business operations.